- SIMONA

SUSTAINABLE

PRODUCTS

Why plastics can be sustainable

Plastic products have many advantages – including their durability, excellent resistance to aggressive chemicals depending on the material and therefore decades of use, low weight and good recyclability. When used correctly, plastics are sustainable.

Sustainable management and growth has always been a fundamental principle at SIMONA. We are therefore constantly working on reducing the consumption of resources for plastics production and expanding recycling systems – at all levels.

New generation of plastics: durable, ingenious and sustainable.

For us, EcoPlastIQ stands for a new generation of plastics based on sustainable raw materials. These include circular materials such as recycled waste plastics or regenerative raw materials or their granulates, which can come either from biological source materials (e.g. rapeseed, sugar cane, etc.) or biological waste (fats, oils, etc.).

Common characteristic: A significantly lowerCO2 footprint compared to conventional alternatives and the use of oil-free or oil-saving resources. EcoPlastIQ identifies all SIMONA products that meet these criteria and stand for premium ecological quality.

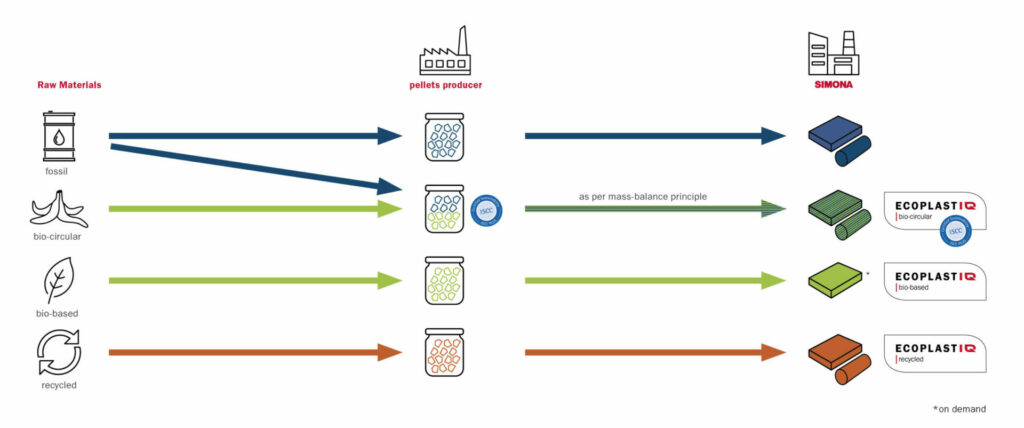

FROM RAW MATERIAL TO PRODUCT

The mass balance principle in the plastics industry promotes the introduction of innovative plastics that do not require fossil raw materials for production. In order to maintain consistent material qualities and proven production processes, granules made from renewable raw materials are added at an early stage of the production process in the mass balance process.

In this way, the material properties of the plastic are fully retained. By conserving finite fossil resources (crude oil), the CO2 footprint of the products is significantly reduced. Proof of the sourcing of sustainable raw materials and their inclusion in our mass-balanced products is confirmed by ISCC PLUS certification.

- APPRECIATION

SIMONA® ECOPLASTIQ

BIO-CIRCULAR (ISSC PLUS)

ISCC PLUS certified

ISCC stands for International Sustainability and Carbon Certification and is the first EU-accredited certification system for sustainability and greenhouse gas reduction that can be applied worldwide to all types of biomass and biomass derivatives. ISCC PLUS is based on a mass balance approach that promotes the use of sustainable raw materials. The special thing about this is that the end product meets the same quality standards compared to the proven property profiles of fossil-based plastics.

- APPRECIATION

SIMONA® ECOPLASTIQ BIO-BASED

We define bio-based plastics as polymers that are made from renewable raw materials and/or are biodegradable. We differentiate between plastics that are based on renewable resources such as starch, sugar or plant residues and those that decompose automatically under certain conditions in a biological decomposition process.

- APPRECIATION

SIMONA® ECOPLASTIQ RECYCLED

Recycling existing plastics for a second or further life cycle makes it possible to close material cycles and significantly reduce the CO2 footprint. That is why we will increasingly use recycled materials in our production process.

We develop innovative approaches for returning our products to a wider product cycle together with our strategic partners.

Recycling zusammen mit

In Zusammenarbeit mit dem Umweltdienstleister der Schwarz-Gruppe, “PreZero”, haben wir ein wegweisendes Projekt gestartet, das darauf abzielt, ein effizientes System zur Rücknahme von Produktionsabfällen unserer Kunden zu etablieren.

Unser Ziel ist es, aktiv zur Schließung von Materialkreisläufen beizutragen und gleichzeitig eine bedeutende Reduzierung des CO2-Fußabdrucks unserer Produkte zu realisieren.

In einem ersten Schritt konzentrieren wir uns auf die Materialkreisläufe unserer deutschen Kunden, mit dem klaren Vorhaben, diesen Fokus in Zukunft auf weitere Regionen auszudehnen. Die gegenwärtige Ausrichtung auf die Materialkreisläufe unserer deutschen Kunden bildet dabei den Ausgangspunkt für eine künftige Erweiterung.

Wir möchten so dazu beitragen, Materialkreisläufe zu schließen und eine Reduzierung des CO2-Fußabdrucks unserer Produkte erreichen. Zunächst werden wir uns auf die Materialkreisläufe unserer deutschen Kunden fokussieren und anschließend weitere Regionen involvieren.

SIMONA Peak Pipe Systems, unsere Tochtergesellschaft in Großbritannien, konnte im Jahr 2022 bereits mehr als 2.500 Tonnen recyceltes Material für eine Vielfalt an Produkten einsetzen und verkaufen.

Wir möchten so dazu beitragen, Materialkreisläufe zu schließen und eine Reduzierung des CO2-Fußabdrucks unserer Produkte erreichen. Zunächst werden wir uns auf die Materialkreisläufe unserer deutschen Kunden fokussieren und anschließend weitere Regionen involvieren.

- APPRECIATION

Our ecological products

What all EcoPlastIQ plastics have in common is their contribution to environmental and climate protection, which manifests itself in

- their lower CO2 footprint,

- the conservation of fossil resources,

- wide range of applications and good recyclability,

- best possible material properties such as durability, lightness and strength

Sustainable responsibility

Part of life. Part of sustainable solutions around the globe.

SIMONA products not only protect the environment during production, but can also be used to protect it. SIMONA’s products provide sustainable solutions for energy supply as well as for safety-critical and environmentally relevant applications. There is a need for solutions in abundance – in 2015, the United Nations adopted 17 Sustainable Development Goals (SDGs). These 17 SDGs, accompanied by 169 targets, individually address global challenges. Simona’s products contribute to a sustainable economy in different ways and contribute to various goals.

Zero Hunger

“Zero Hunger“ is the second United Nations Sustainable Development Goal and aims to achieve a world without hunger by promoting food security.

SIMONA products for food production and processing can help to achieve this goal.

Fields of application:

Installations for land-based aquaculture

Lining of food silos

Chain guides and conveyor belts in the food and beverage industry

Extruder screws made from SIMONA solid rods for the production of foodstuffs

Fields of application:

- Installations for land-based aquaculture

- Lining of food silos

- Chain guides and conveyor belts in the food and beverage industry

- Extruder screws made from SIMONA solid rods for the production of foodstuffs

Good health and well-being

The ultimate aim of Sustainable Development Goal 3, “Good health and well-being“, is to ensure healthy lives and promote well-being for all. In this context, the availability of high-quality medical products and technologies plays a crucial role.

The SIMOLIFE product group features plastic products that help to improve healthcare relating to prosthetics and orthotics.

Fields of application:

Manufacture of orthoses

SIMONA plastics for the design of prostheses

Housings for medical devices, such as CT scanners

Fields of application:

- Manufacture of orthoses

- SIMONA plastics for the design of prostheses

- Housings for medical devices, such as CT scanners

Clean water and sanitation

Sustainable Development Goal 6, “Clean water and sanitation“, aims to ensure access to clean water and promote sustainable water management.

SIMONA can build on a pedigree of excellence in the field of water and wastewater treatment, desalination and drinking water production – centred around the development of technologically advanced plastic products that promote efficient water use. Plastics deployed in water infrastructure installations provide the basis for durable solutions when it comes to reliable drinking water supply and wastewater treatment. Innovative monitoring technologies help to minimise water loss and conserve resources through early detection of leaks, while our double-containment pipes offer additional safety.

Fields of application:

Pipes and fittings for the transport of water and wastewater

Pipes and fittings for the desalination of seawater

Double-containment pipe systems for environmental protection zones

Double pipe systems for transport of aggressive and environmentally hazardous substances

Fields of application:

- Pipes and fittings for the transport of water and wastewater

- Pipes and fittings for the desalination of seawater

- Double-containment pipe systems for environmental protection zones

Affordable and clean energy

The seventh Sustainable Development Goal, “Affordable and clean energy“, is about ensuring access to affordable, reliable, sustainable and modern energy for all. SIMONA supports this goal by manufacturing intermediate products designed for the utilisation of renewable energy.

The use of plastics in the manufacture of renewable energy technologies helps to boost the efficiency of these systems and extend their service life.

Fields of application:

Innovative cable ducts for wind farms

Plastic pipes for low-ex heating applications

Plastic pipes for district heating applications

Fields of application:

- Innovative cable ducts for wind farms

- Plastic pipes for low-ex heating applications

- Plastic pipes for district heating applications

Industries, Innovation and Infrastructure

Sustainable Development Goal 9, “Industries, Innovation and Infrastructure“, seeks to build more resilient infrastructure, promote sustainable industrialisation and foster innovation. Semi-finished products and piping systems for the chemical process industry and infrastructure form an integral part of SIMONA’s core business. Offering excellent chemical resistance, SIMONA products are used in safety-critical and environmentally relevant industrial and infrastructure applications.

Thanks to their superior corrosion resistance, the materials guarantee the longest possible service life while at the same time utilising efficient and climate-friendly production technology.

In addition, the company is committed to process innovation in order to make not only the product itself but also its downstream processing more environmentally friendly. A prime example of this is the trenchless installation method, which minimises the environmental impact.

Fields of application:

Metal surface treatment and corrosion protection in industrial applications

Products for the manufacture of chemicals and primary commodities

Drainage pipes for the drainage of railway tracks

Products for the manufacture of semiconductors and battery cell production for the automotive industry

Fields of application:

- Metal surface treatment and corrosion protection in industrial applications

- Products for the manufacture of chemicals and primary commodities

- Drainage pipes for the drainage of railway tracks

- Products for the manufacture of semiconductors and battery cell production for the automotive industry

Sustainable Cities and Communities

The eleventh of the seventeen Sustainable Development Goals, “Sustainable Cities and Communities“, is about making cities and human settlements inclusive, safe, resilient and sustainable. Among other things, SIMONA manufactures products that can be integrated into low-emission transport development.

Fields of application:

Battery housings for e-mobility applications

Research into alternative propulsion systems, e.g. hydrogen tanks

Equipment for public transport

Products for urban farming und urban gardening

Fields of application:

- Battery housings for e-mobility applications

- Research into alternative propulsion systems, e.g. hydrogen tanks

- Equipment for public transport

- Products for urban farming und urban gardening

Responsible consumption and production

The focus of the twelfth Sustainable Development Goal, “Responsible consumption and production“, is on improving efficiency in the use of resources, reducing waste and thus minimising the environmental impact. SIMONA has initiated extensive changes to make its production more sustainable and manufacture products with greater sustainability in mind. Thus, it plays a key role in realising the above-mentioned goal. The company is not only working on new processes and technologies for the production of plastics that are more environmentally friendly, energy efficient and resource-saving but is also integrating other aspects such as the development of a closed-loop system. This includes partnerships with recycling companies such as Prezero in Germany, take-back and reworking for customers at its plant in China and the use of more sustainable commodities such as ISCC-certified materials.